Get a Free Operational Efficiency and Optimization Analysis

Take advantage of Pacific Integrated Handling’s expertise and experience.

Custom Automated Material Handling and Framing Solutions - 1 (888) 550 5888

Posted by Pacific Integrated Handling

Pacific Integrated Handling was contacted by a new customer regarding design and delivery of two new assembly lines. Normally this would be just another day designing with Bosch Structural Framing but this customer needed Design, Order Processing, New Customer Set up, Assembly and Delivery in less than 5 weeks. No other manufacturer they had contacted were able to promise a successful delivery of their custom designed layout in such a short window but PIH was up for the challenge.

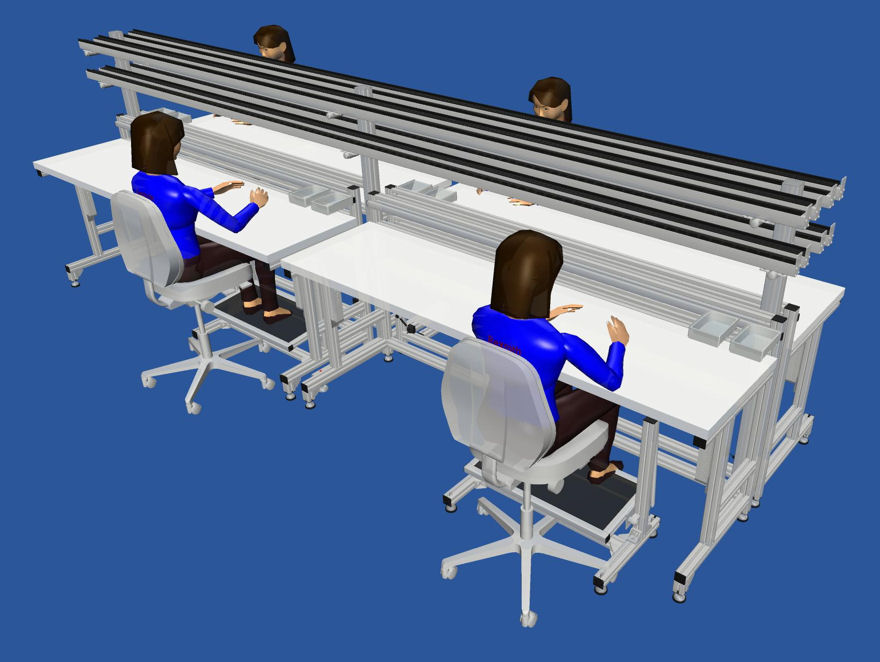

Our customer had successfully mocked up their assembly line workstations, carts and flow racks using cardboard and foam in real scale. Our team, PIH and Bosch, was able to use Bosch MT Pro software package to design and quote these materials in 48 hours. We designed at the customer site for quick visual acceptance and review. Bosch MT Pro software is available at no charge to the customer. It was a very valuable piece of this project to expedite design information.

Pacific Integrated Handling has over 20 years of experience providing our customers with cleanroom approved Bosch Structural Framing projects. Bosch supports cleanroom installations with flat sided profiles, stainless and zinc plated components, anodized aluminum surfaces, t-slot covers and finishing hardware like radius compensators. PIH also has a catalog of in-house clean room components compatible with Bosch framing manufactured in our own machine shop in Tacoma, WA.

In addition to the cleanroom specifications of this demanding project, Bosch and Pacific Integrated were also able to provide ESD hardware for this electric component build workstation. We were able to procure ESD laminate table tops, assembler strap plugs and design the workstations, carts and racks to accommodate their additional needs for ESD while remaining on schedule.

Pacific Integrated Handling was able to ship the first location within 5 weeks, including over 25 assembled workstations, 4 carts and 3 flow racks. Our team went above and beyond, loading trucks on Saturday when the customer logistics truck did not show up on Friday as scheduled. The customer expressed “thank you and the shop floor team very much for working so hard and pushing the order through to ship”. All of the designs are cleanroom compatible, ESD safe and manufactured to the high standards of Pacific Integrated Handling.

Take advantage of Pacific Integrated Handling’s expertise and experience.