Custom Automated Material Handling and Framing Solutions - 1 (888) 550 5888

Bosch Rexroth Tightening Systems

Rexroth Tightening Systems use advanced digital control technology and long-lasting electric motors to provide scalable assembly tightening solutions for all automated and manual tightening tasks.

(click to enlarge)

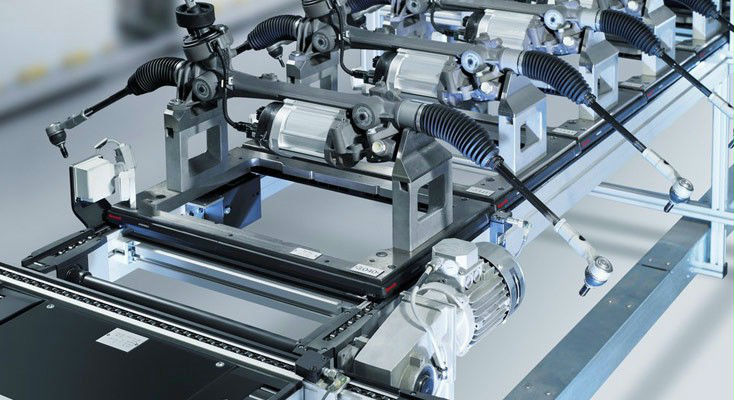

Bosch Rexroth Tightening Systems

Rexroth Tightening Systems use advanced digital control technology and long-lasting electric motors to provide scalable assembly tightening solutions for all automated and manual tightening tasks.

Request for Information

Whether you’re assembling automobiles, dishwashers or wind turbines, every connection must be secure, reliable, and accurate. Rexroth Tightening Systems provide manufacturers the assembly tools they need to sustain high volume, high-quality assembly operations. The proof is in the performance: All Rexroth tightening components are designed to withstand over one million maintenance free tightening cycles under full load.

Handheld tools

Powerful, ergonomic and easy to use.

- High level of reliability through the accurate measurement of tightening parameters and digital result transmission.

- Reduced operator fatigue through ergonomic design and light weight construction.

- Easy operation via user friendly controls and indicators.

OPEXplus Digital Torque Wrench

The reliable OPEXplus digital torque wrench can measure both the torque and the angle of rotation. It covers a range of torques from 3 to 800 Nm, and it transfers the tightening results to any IT system without the need for additional control. The wrench allows fatigue-free work with its ergonomic design. The wrench‘s camera-based scanner uses an optical aiming device to read in barcodes and QR codes and transfer them to higher-level systems quickly and correctly.

OPEXplus torque tools are recognized in networks via the embedded WiFi module. When a tool in an assembly line is changed, the module can simply be plugged into the new screwdriver. The supplied software allows parameterization via a hotspot, the customer network or a serial interface.

The intelligent OPEXplus transmits the tightening results with a tightening curve, as well as maximum torque and angle of rotation, directly to any of the user’s IT systems without the need for additional control. OPEXplus supports popular protocols such as OpenProtocol, IPM or XML. A standard 21700 lithium-ion rechargeable cell supplies the power.

An LED display ring on the handle is visible from all directions and shows the tightening process and result. An optional vibration module providing touch confirmation is available as well. The color display allows the ergonomically optimized torque and angle-controlled wrench to be operated intuitively. The tool housing is made of a robust titanium-aluminum alloy with an anti-slip handle cover.

Wireless battery tools

Intelligent tightening tools with a high degree of security and flexibility.

- The highest degree of process security due to transducerized measurement of torque and angle.

- Process reliability via an integrated onboard controller and wireless buffered data transfer – works even in weak signal areas.

- Easy assembly even in hard to reach applications.

- Clear feedback to the operator via an integrated color display.

Stationary tightening spindles

Modular construction provides flexible solution for a wide range of applications

- Redundant transducer technology meets the highest levels of reliability conforming to VDI standards.

- High performance for the most demanding applications in either manual or automated assembly systems.

Informative Videos

You May Also Be Interested In:

Print this Page

Print this Page